Dental crown alloys –

How to decide what kind of dental alloy should be used to make your crown.

If the type of crown being made for your tooth has a metal component, your dentist, possibly after getting some input from you, will need to make a decision about the kind of dental alloy that will be used for its construction.

What kinds of dental crowns contain metal?

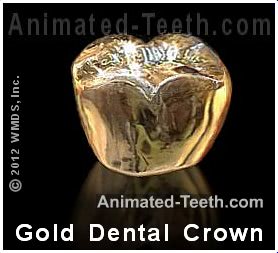

- Obviously, all-metal crowns do Details | Pictures. Examples include the “classic” gold dental crown but also, at the other extreme in alloy choice, the non precious metal crown.

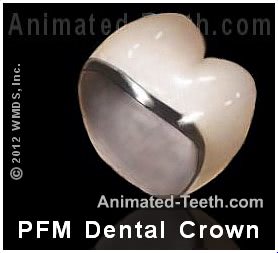

- And although the part of the restoration you see is porcelain covered, porcelain-fused-to-metal crowns (PFM, PFG, and PTM restorations) Details | Pictures do too.

What options exist?

a) There are 3 basic kinds of dental alloys.

The types of alloys used in the fabrication of dental crowns generally fall into one of 3 categories. They are: high noble (precious), noble (semi precious), and non-noble (non precious). (We explain the specifications associated with each category below on this page.)

As you might guess from these names, this classification system is based on the alloy’s composition. Both in terms of what types of metals it contains, and in what percentages. Of course, the question then comes, why does the type of alloy used matter?

b) The specific alloy chosen is important because each kind has different physical properties.

By no means are all dental alloys just alike. Instead, the composition of each kind gives it its own unique physical characteristics, which in turn gives a crown made using it comparative advantages and disadvantages.

These differences can involve issues that are:

- Important to you. – An obvious example is the metal’s color. Precious, semi precious, and even non precious alloys can have either a “yellow” (golden) or “white” (siver) coloration. Also, issues like metal allergies can be important too.

- Important for your crown’s fabrication and success. – Factors like how easy the metal is to work with, or how well porcelain bonds with it, can affect your crown’s fit and longevity.

- Financial in nature. – Not only will the type of alloy that’s chosen affect the crown’s cost (for example the cost difference between precious vs. non precious metals) but it may even affect the restoration’s level of insurance coverage.

The remainder of this page explains each of the above considerations in greater detail. However, and as you’ll find out below, if cost is not a factor then the alloy having the highest precious metal content typically makes the best choice.

Dental alloys – What you need to know when choosing one for your crown.

Some quick background information.

For starters, and possibly contrary to what you might have thought, all dental crowns that have a metal component are made using specifically formulated dental alloys. No pure metals are ever used for crown fabrication, not even gold.

The reason for this is because for this kind of application, the physical properties of alloys are far superior. For example:

- Gold in pure form is too soft to give a crown good wear characteristics. (Like the wear caused by the teeth that chew against it.)

- A pure gold crown would tend to deform (distort in shape) as it’s perpetually subjected to chewing forces.

- As opposed to pure gold, base (non precious) metals included in alloy formulations form oxides that enhance metal-to-porcelain bond strength which, of course, is of utmost importance for porcelain-fused-to-metal crowns.

Dental alloy classifications – High noble (precious), Noble (semi precious), Non-noble (non precious).

In 1984, the American Dental Association (ADA) set up a three-tiered classification system for dental alloys, based on the types and percentages of metals used in their formulation.

(Since the ADA is also the organization that names and assigns insurance code numbers to dental procedures, these same alloy categories may show on your bill or insurance paperwork. For example: “D2750 crown – porcelain fused to high-noble metal.”)

1) High noble alloys (Precious metal)

This group has a composition that is over 60% noble metal, of which more than 40% must be gold. The elements gold, palladium, platinum, rhodium, ruthenium, iridium, and osmium are categorized as noble metals.

Examples of high noble dental alloys.

- Product: JRVT / Alloy Color: Yellow / Composition: 77% Gold, 13% Silver, 8.5% Copper, 1.0% Palladium, Less than 1% Indium, Iridium, Zinc

- Product: JIV-PF / Alloy Color: Yellow / Composition: 72.5% Gold, 13.5% Copper, 10.2% Silver, 2.8% Platinum, Less than 1% Indium, Iridium and Zinc.

- Product: Noble-Cast 67 / Alloy Color: Yellow / Composition: 64.0% Gold, 23.4% Silver, 3.0% Palladium, 0.1% Platinum

- Product: Encore (White High Noble) / Alloy Color: Silver (white) / Composition: 48% Gold, 40% Palladium, 4.3% Zinc, 3.9% Tin, 3.75% Indium, 0.05% Rhenium

2) Noble alloys (semi precious metal)

These alloys have at least 25% noble metal content.

Examples of noble dental alloys.

- Product: Argenco 20 / Alloy Color: Yellow / Composition: 20% Gold, 20% Palladium, 40% Silver, 18% Indium, 2% Zinc, Less than 1% Iridium.

- Product: Argelite SR+ / Alloy Color: Silver (white) / Composition: 79% Palladium, 8.4% Tin, 5.0% Cobalt, 5.0% Gallium, 2.0% Gold, 0.6% Ruthenium

3) Non-noble (non precious metal)

These alloys are also referred to as base metals. Their noble metal content is less than 25% (they may have none). They often contain large percentages of nickel, cobalt, chromium, or beryllium.

Examples of non-precious (base) dental alloys.

- Product: Argeloy N.P. Supreme / Alloy Color: Silver (white) / Composition: 61% Cobalt, 27% Chromium, 6% Molybdenum, 5% Tungsten, 1% Silicon, Less than 1% Manganese, Iron, Carbon

- Product: Argeloy N.P. / Alloy Color: Silver (white) / Composition: 54.0% Nickel, 22.0% Chromium, 9.0% Molybdenum, 4.0% Iron, 4.0% Niobium, 4.0% Tantalum, 3.0 % Trace elements.

- Product: AalbaDent NPG / Alloy Color: Yellow / Composition: 80.7% Copper, 7.8% Aluminum, 4.3% Nickel, Trace percentages of : Manganese, Iron, Zinc.

▲ Section references – Anusavice

Alloy compositions are taken from manufacturers’ information.

Why does it matter which alloy is used to make your crown?

There are several reasons why it’s important. Some of them affect you directly. Others will be more of a concern to your dentist, or the dental laboratory that makes your crown.

a) Costs – High noble metal alloys are more expensive.

Some of the predominant noble metals contained in dental alloys are gold, platinum, and palladium. And just as you’d expect, the greater the percentage of these precious metals that an alloy contains, the more expensive it will be.

- With restorations where the actual amount (weight) of metal they contain is relatively small, the price difference between using a high-noble (precious) or base-metal (non precious) alloy might be very minor.

(As examples, the metal component of a porcelain-fused-to-metal crown for a lower incisor or upper lateral incisor might be relatively minimal.)

- But in the case where an all-metal restoration is made for a large tooth (like a molar, and especially one that has lost a lot of tooth structure), the cost difference between having a non precious metal crown made and a gold one might be significant enough to affect your decision.

(Here’s more information about the cost for different kinds of dental crowns Crown fees..)

b) Dental plan and insurance policy limitations.

If there’s a third party involved in paying a part of your bill, you might check to see if there are any limitations as to the type of metal that can be used for crowns.

Possible restrictions.

The policy might state that they do not cover the cost of high noble alloys. Or the level of coverage (in terms of your out-of-pocket expenses) might vary according to which type of metal is used.

A dental policy or plan that doesn’t provide coverage for precious metal crowns would be considered limited and disappointing but the use of a semi precious alloy can make a reasonable alternative. Serviceable crowns can be made using non precious metal alloys too. But a policy that limits you to just this choice alone should be considered subpar.

(Here’s more information about insurance coverage for dental crowns. When are they covered? | Restrictions)

This gold crown has a yellow color.

c) Color – Dental alloys can be white or yellow.

Considerations.

- Some dentists feel that using a yellow-colored alloy with PFM crowns gives the restoration’s porcelain a warmer, more natural look.

- If you’re having an all-metal crown placed, you may have a big preference as to its color (deep yellow, yellow, pale yellow, or white).

▲ Section references – Knosp

d) Some people have metal allergies.

Some of the metals included in the formulation of dental alloys used for crown fabrication have been shown to trigger an allergic reaction in some patients. Nickel, chromium, palladium, and cobalt have all been implicated.

- It’s estimated that 10 to 20% of females have an allergic response to nickel. The incidence rate for men is lower, possibly as low as 5%.

- Sensitivity to palladium generally runs about 1/3rd that of nickel. But those who are are almost always allergic to nickel too. (We’ve found conflicting sources as to whether the reverse is true.)

- The allergic response experienced is typically benign. But its associated itching can affect the person’s quality of life. Besides just the mouth, other parts of the person’s body may be affected too.

- In cases where a question about metal sensitivity exists, prior to restoration construction a dermatological patch test can be used to evaluate the patient’s status.

▲ Section references – Sakaguchi, Zhang, Knosp

Alloy alternatives do exist.

If the metal that triggers the response can be identified, an alternative alloy can usually be found.

- Base (non noble/non precious) alloys, as opposed to noble or high-noble ones, are typically associated with a larger release of nickel, chromium, and cobalt ions, and thus their use may be indicated.

- While palladium is found in many high-noble formulations, some palladium-free products do exist (see table above). Additionally, some of these formulations don’t contain any of the other metals commonly associated with allergies either.

e) The physical properties of the alloy are an important consideration.

Some dentists and dental laboratories have a set opinion about which kinds of dental alloys they will even consider working with. A part of this reasoning may be because their primary goal is simply getting the job done right, the first time.

They know that any difficulties or problems that crop up will just end up costing them money. So, if choosing a certain type of alloy makes getting a positive result more likely, then that’s the one they’ll want to work with.

The advantages of precious dental alloys.

High noble alloys constitute the “gold standard” of dental metals. (All others are compared to them.) And dentists and dental technicians generally much prefer working with them, especially those that have a high gold content, because:

A porcelain-fused-to-metal dental crown.

- They are the easiest to cast (the process by which metal crowns are made) and polish.

- Restorations made using high-nobles are known for their accurate fit on their tooth. But also, this grade of alloy is relatively malleable so the fit of the restoration can be adjusted if needed.

- High noble alloys generally offer the most predictable bond with porcelain, a factor that can influence how long a porcelain-fused-to-metal crown will last Crown longevity studies..

- The noble metals these alloys contain give them superior corrosion resistance.

▲ Section references – Anusavice, Sakaguchi

Which type of alloy should you choose for your dental crown?

As mentioned above, assuming that cost is not a factor, opting for a high noble dental alloy (precious metal alloy) makes the best choice. However, if cost alone is your primary determiner, a non precious metal crown would be your least expensive option.

Page references sources:

Anusavice KJ, et al. Phillip’s Science of Dental Materials. Chapter: Dental Casting Alloys and Metal Joining.

Knosp H, et al. Gold in Dentistry: Alloys, Uses and Performance.

Sakaguchi R, et al. Craig’s Restorative Dental Materials.

Zhang X, et al. A comparative analysis of metal allergens associated with dental alloy prostheses and the expression of HLA-DR in gingival tissue.

All reference sources for topic Dental Crowns.

Comments.

This section contains comments submitted in previous years. Many have been edited so to limit their scope to subjects discussed on this page.

Comment –

Full gold crown

What is a reasonable additional cost for a full gold crown vs a standard high noble metal

Zach

Reply –

As our page here mentions, pure gold doesn’t make a good choice for dental crowns. In the simplest terms, it’s too soft a material and simply wouldn’t result in a durable restoration.

As that same page discusses, high noble dental alloys can be white or gold (yellow) in color. We Googled around a bit to see what the comparative prices for these are.

Probably due to the fact that that the prices of these alloys change daily, we only found one manufacture who stated prices. While what we saw wasn’t a true apples-to-apples comparison, the white alloy actually cost more than the yellow one.

What did catch our eye was the price of an ounce of pure gold on that day was around $1216 (London fix).

The cost per ounce for the yellow dental high noble dental alloy was $1142, a rather marginal difference considering a crown for a molar would probably be in the neighborhood of 1/10th of an ounce.

Staff Dentist

Comment –

Cobalt in hi noble.

I am allergic to cobalt. I had dental restoration on all teeth upper. I did not realize I was getting metal. A year later I went for a cleaning at a different dentist office. He thinks I am allergic to metal because of the condition of my gums. How can I find out if this is true? I have 2 bridges that are not permanently in because he used a cement that would be able to come out if needed.

Lpjf

Reply –

Here’s a relevant resource to your situation.

This research study evaluated patients suspected of having allergies to dental materials, like cobalt found in dental alloys.

In its “Materials and methods” section, it discusses the use of a “patch test” (a skin test most commonly performed by a dermatologist) to identify the nature of each patient’s allergy.

The same paragraph then also mentions “Particular attention was paid to mucosal (gum tissue) changes in the area of contact with dental materials.”

So, the appearance of the tissue in the area of your crown is the tipoff. Then patch testing is the common method used to diagnose the specific allergen(s) (cause of the allergic reaction).

If perchance making new crowns is found to be indicated, here is our page that describes various types of non-metallic (all-ceramic) dental crowns. Different types have different advantages for front vs. back teeth, or use in dental bridge construction.

Staff Dentist